Cool robot components I made

← Aug 9, 2022

This is some of my work when I was on the FTC 8565 Technicbots highschool robotics team.

Drivetrain

Cool facts:

- Special attention was given to the motor mounts so that we could replace motors easily.

- We used bearings as tiny wheels to let us ride along the wall! I learned this from Robert Cowan. Unfortunately, this may have bit us at the world championship. There, some teams were using large or soft wheels, and we suspected it may have made their robot more consistent when it aligns against walls while driving autonomously.

- One detail is that the motors are shifted towards the outside to make room for bolting things to the inside wall.

- There’s some fancy stuff in the bevel gear assembly to fit them in such a tight space while keeping them easy to assemble and disassemble.

Foam ring shooter, design 2 (Straight shooter)

The first design was bad, so we’ll skip that.

Cool facts:

- Early in this season I spent a week learning how to make custom bevel gears (Look at the 80 degree bevel gear!). In hindsight the benefit was negligible, but it was really fun. However, taking advantage of custom gears to make all sorts of angled components revealed mistakes in my CAD parts. I had to learn the hard way that what’s considered horizontal or vertical is relative to the component’s local origin, which can be rotated relative to the overall model origin. So, a horizontal sketch line in one sketch might be skewed from horizontal sketch lines in other sketches.

- That green wheel on the top was prototyped with spare parts because our original design didn’t work.

- If a timing belt pulley is too small, it bends too hard around the corner gets damaged. If it’s too large, the surface speed is too fast and it gets damaged. The speeds at which damage happens is way higher than anything we’ll use, but as a perfectionist, I just had to find the perfect size that’d allow the maximum RPM.

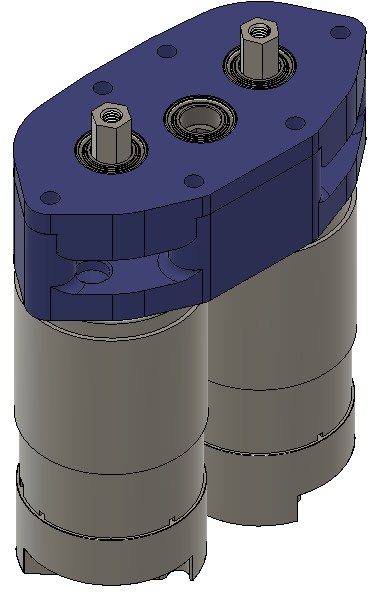

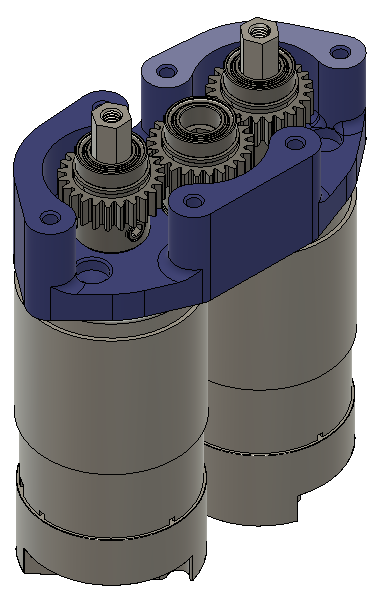

Cool gearbox

This design was really elegant and made me very happy, but in hindsight, it’s only elegant because it’s so minor.

Cool facts:

- Housing simplified into only two parts for easy assembly

- Shroud to block gear lubricant from escaping, but also holes to let us add more lubricant.

- One mistake is that I added way too many screw holes. We only needed two screws.

Foam ring shooter, design 3 (Curved Shooter)

Cool facts:

- A bump at the beginning probably prevents rings from rolling into the flywheel and misfiring. We never got time to try removing it. It might also give us extra traction to accelerate the rings.

- The exit shape of the shooter’s rounded wall is easily removable, and we tested different shapes for it. It’s pretty important for accuracy, since that part controls how the rings decompress.

CVT Swerve Drivetrain

I was very inexperienced when I made this and bit off way more than I could chew. Made a ton of mistakes and gave myself a very long feedback loop.

Mistakes:

- Didn’t test the most novel and failure prone component before building everything. We found out that V-belts are significantly less flexible than we thought, making this design work poorly.

- Wasted time on micro-optimizations, like pocketing, before I knew if the parts would work.

- I designed for the wrong manufacturing style, and hackily fixing this added a ton of unnecessary effort and complexity. I used the plate & spacers approach as if we had a CNC router that made large, 2D parts, but we only had a 3D printer that made small, 3D parts.

The only part of this project that I’m happy about is the the theoretical V-belt path calculator. We needed it to calculate the pulley sizes necessary to vary the gear ratio by 2x.